Labelling Machine for Diverse Industry Requirements

Your branding and label quality is your product's flagship and often influences the customer's purchasing decision. With 40 years of experience in developing and manufacturing labellers, GERNEP is a competent partner for high-quality equipment. Our labelling range includes glass, metal, and plastic materials and different containers standard in the beverage, food, consumer healthcare, and non-food industry.

Technical Features

Base Machine

- Advanced self-adhesive and wet glue units in collaboration with Krones AG

- Interchangeable labelling units – docking according to the plug-and-label principle

- Newly designed guards concept for maximum accessibility and improved ergonomics

- Optimised sealing of the baseplate drive

- Optional installation of multiple (servo-driven) infeed screws for processing different shaped bottles

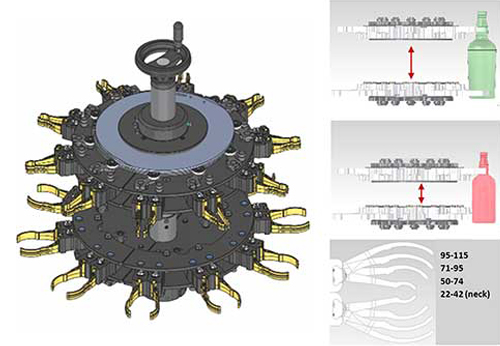

Unigrip - Universal Starwheel

- Processing of different bottle diameters with just one universal starwheel

- Maximum flexibility in product labelling

- Minimisation of necessary format part changes and production downtimes

- Cost reduction for large format variations

- Reduction of storage space required for format parts

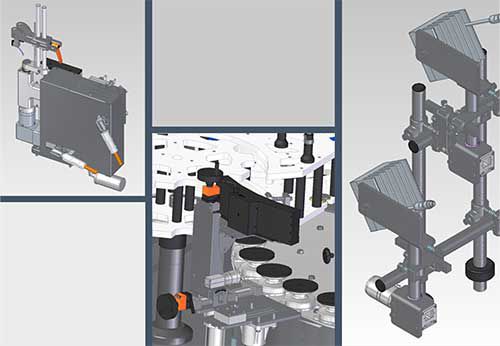

Orientation and Control Systems

- Wide range of advanced orientation and control systems for different customer requirements

- Different kind of sensors available to detect container characteristics like embossing, debossing, seam, graphic etc.

- Compact camera design for easy integration in machine layout

- High resolution cameras and lenses

- 360° bottle orientation

- Increased production efficiency

- Low maintenance and high reliability

- Flexible configuration and material compatibility

Customer Advantages at a Glance

- Flexibility

Ability to handle a wide range of products with just one machine

Reduction in investment costs and increase in productivity - Efficiency

Reduced setup and format change times leading to an increased machine uptime - Hygiene

Compliance with hygiene regulations

Reduced downtime for cleaning with focus on food product manufacturing environment

- User-Friendliness

Fewer operator errors due to simplified trainings and improved operator comfort - Advanced Technology

Optimised process control, modern digitalisation solutions, reduced waste for sustainability

Our Labelling Systems

Flexible labelling options: Our labellers can operate one gluing system or be variably equipped to employ different gluing systems.

Self-adhesive labelling

Cold glue labelling

Hotmelt labelling from the roll

Hotmelt labelling from the magazine

GERNEP Rotary Labeller

Proven technology for current requirements: It is still possible to order our proven GERNEP rotary labelling machines with optional equipment such as integrated date coding, camera alignment or sensors for label inspection.

GERNEP Soluta

GERNEP Labetta

GERNEP Rollfed

GERNEP Rollina

GERNEP Linear 1SK / 2SK

The ideal starter model for small capacities: Despite its compact size, our self-adhesive linear labeller shines with many variation options and is easy and intuitive to operate. Equipped with modern self-adhesive units, it ensures precise labelling.

- Output: up to 2,500 containers / hour

- Integration of 1-2 self-adhesive labelling dispensers

- Processing of front, back and wrap-around labels